Ventilation air grille diffuser

air vent manufacturer since 2002

Vairtech

Vairtech  2025-09-30

2025-09-30

Unlock Higher Profits & Smoother Production: How Vairtech Machines Solve Your Biggest Challenges

Tired of production bottlenecks, high labor costs, and inconsistent quality? At Vairtech, we engineer machinery that doesn’t just perform tasks—it transforms your production line. Here’s how our equipment delivers tangible benefits to your business:

For manufacturers struggling with slow welding speed and high labor dependency.

✅ Cut Waiting Time by 50%:

Dual stations allow loading/unloading while welding—no more machine idle time.

✅ Slash Training Costs:

Easy programming via teaching pendant. New operators learn quickly through video guidance.

✅ Eliminate Post-Weld Grinding:

Laser precision ensures clean, strong welds that are ready to use—saving time and finishing costs.

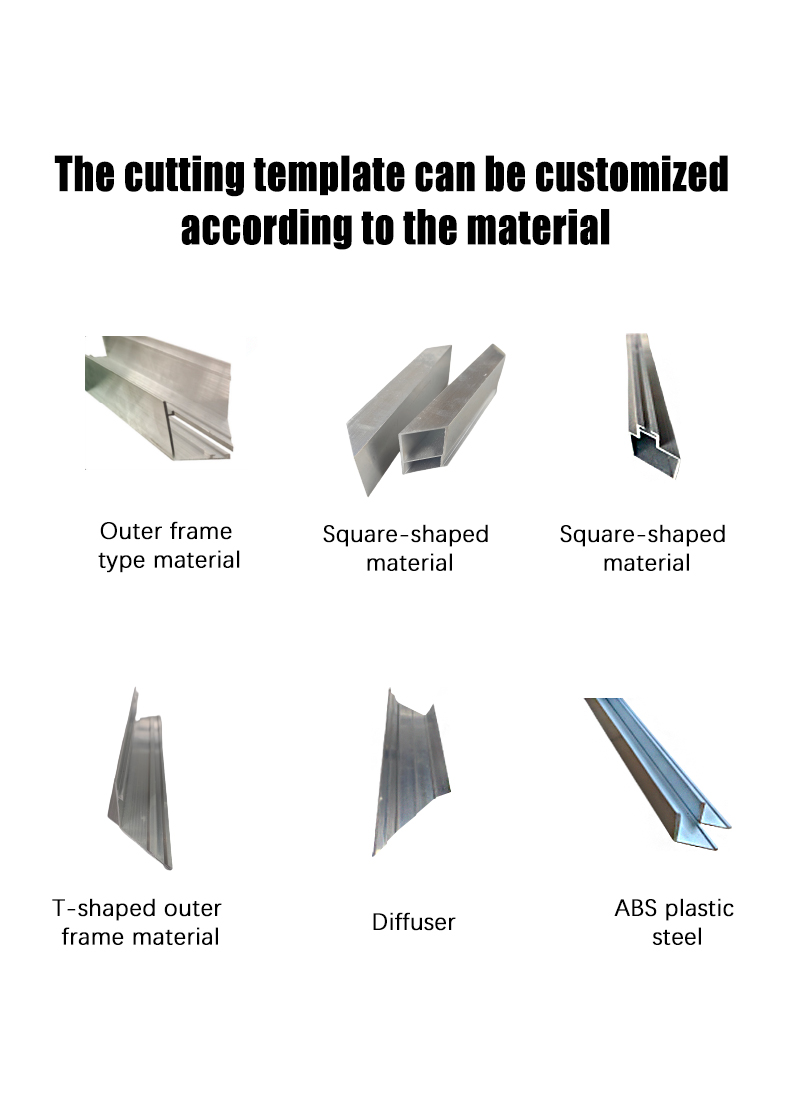

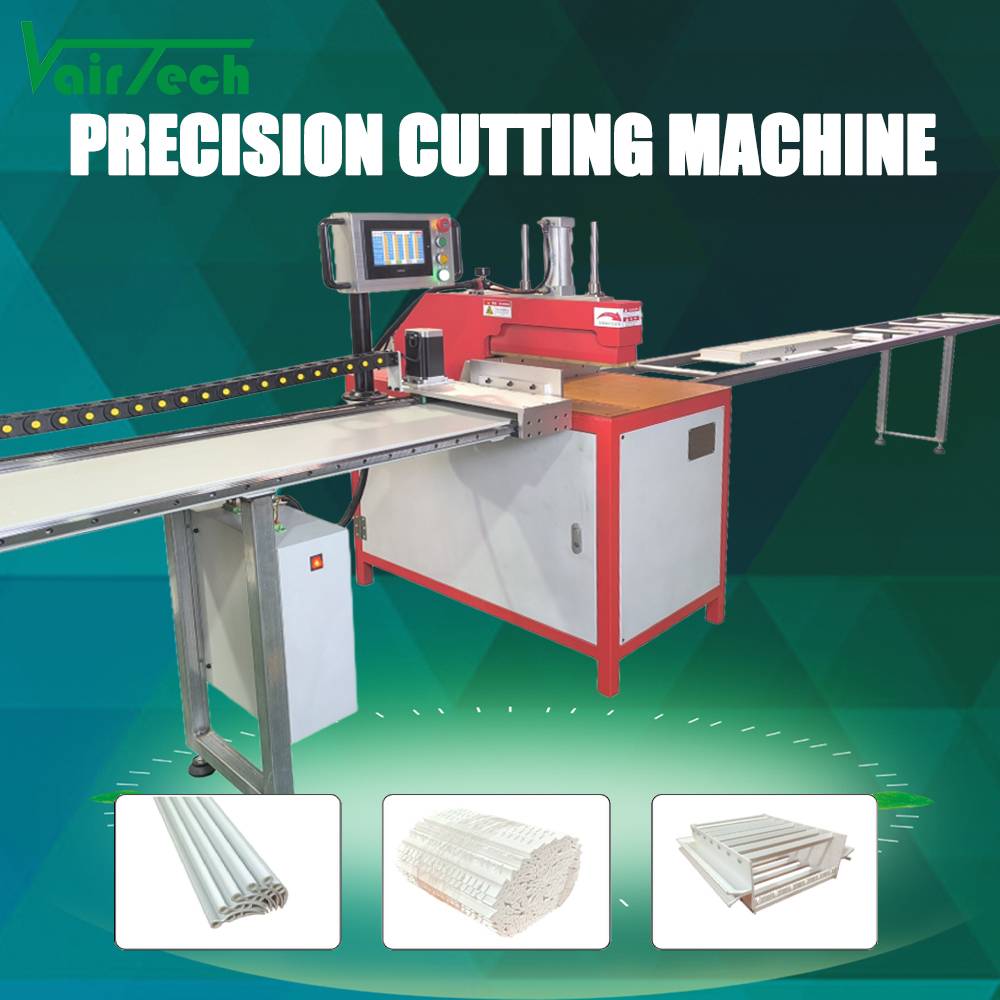

Ideal for businesses needing fast, accurate cutting and punching in one step.

✅ Boost Output to 450 Pieces/Hour:

Automate feeding and cutting to meet tight deadlines effortlessly.

✅ One Machine, Multiple Operations:

Integrate cutting and punching—avoid material handling between stations.

✅ Run by Any Operator:

Simple touchscreen input lets one worker manage multiple machines.

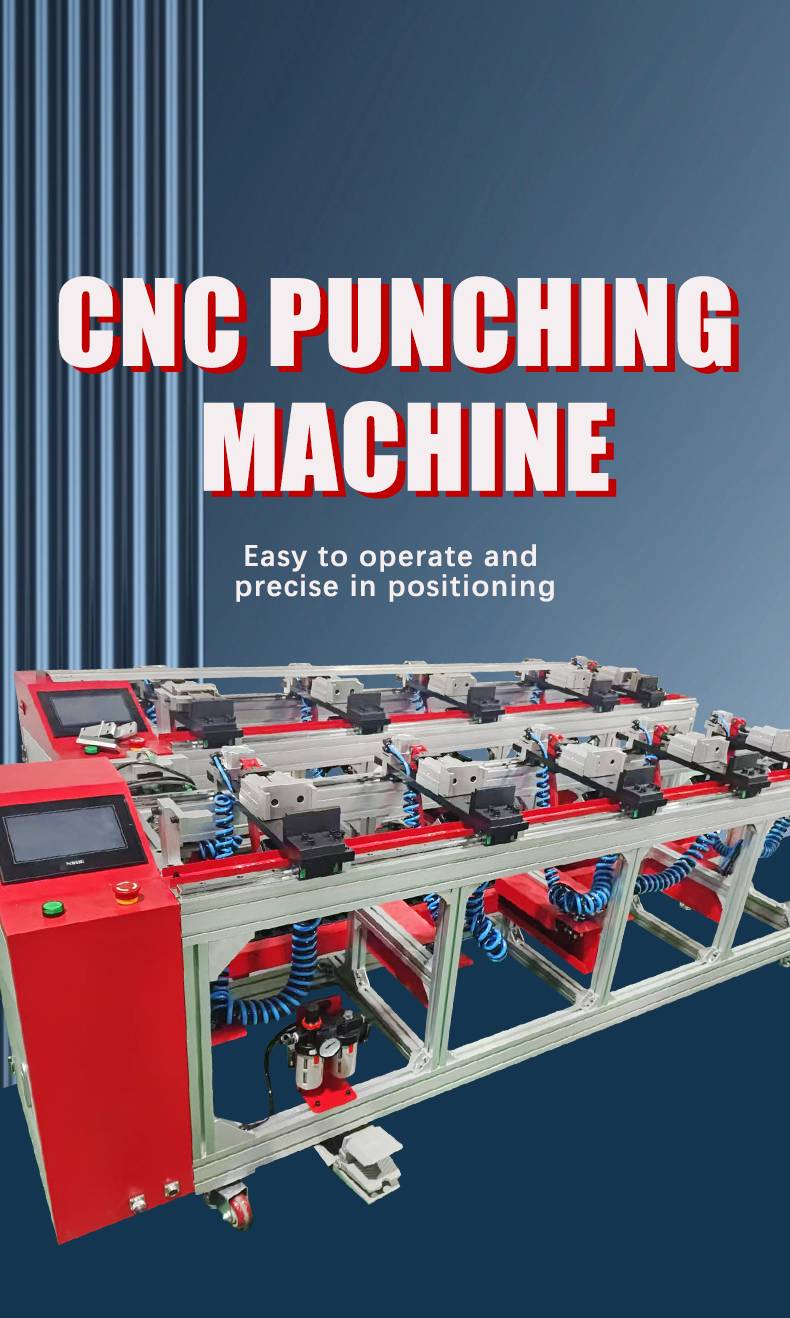

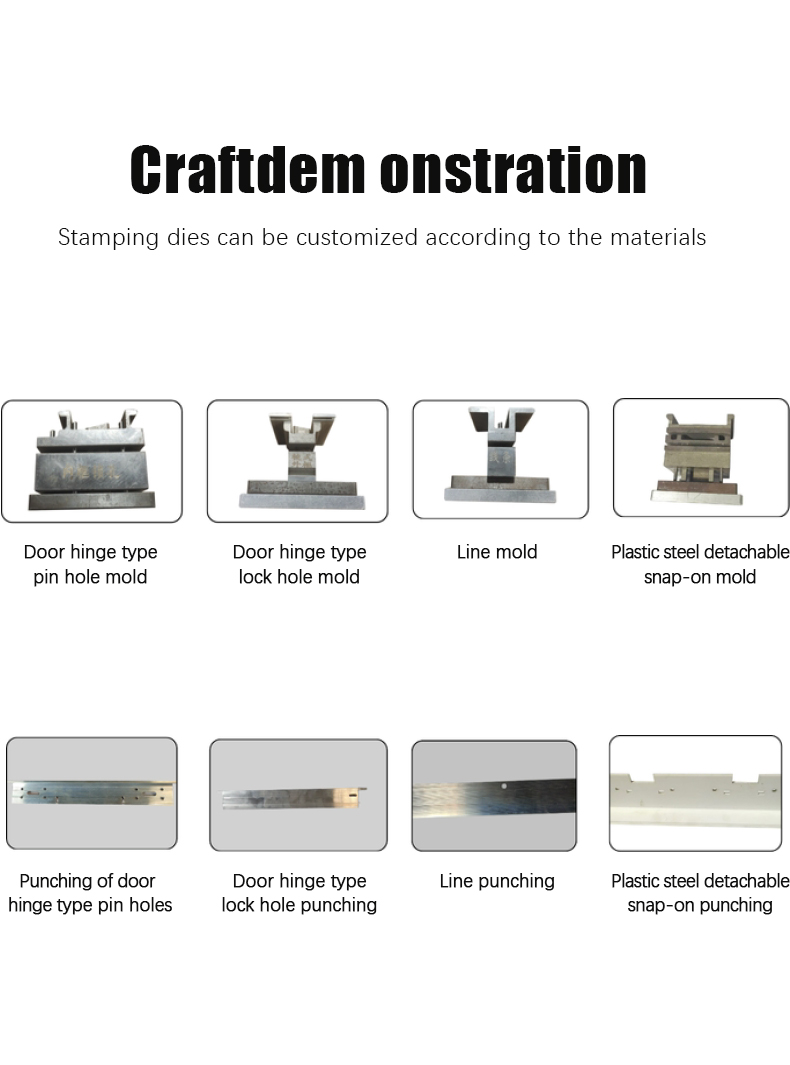

Perfect for workshops handling varied punching tasks with frequent changeovers.

✅ Change Molds in Seconds:

Quick plug-and-pull system adapts to different hole patterns rapidly.

✅ Punch Two Profiles at Once:

Double your efficiency with synchronized left-right punching.

✅ No Experience Needed:

Smart CNC system auto-calculates hole spacing—just input dimensions and go.

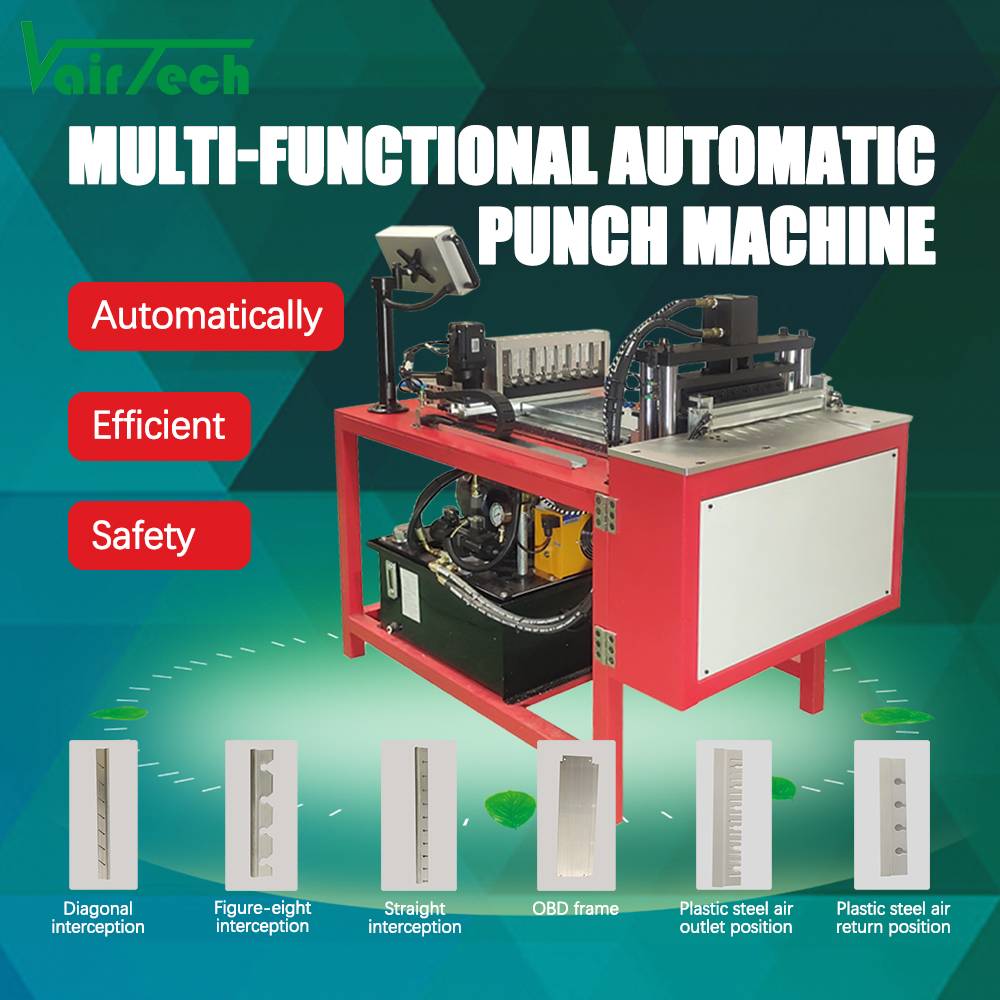

For factories producing diverse air outlet profiles with tight timelines.

✅ Handle 170+ Profile Types:

Configure up to 16 mold sets for unmatched flexibility.

✅ Full Automation, Zero Stress:

Automated feeding, stamping, and ejection—reduce labor and human error.

✅ Safe & Simple:

No manual intervention needed. Intuitive controls and low maintenance.

When every millimeter matters in your final product.

✅ Achieve ±0.1mm Accuracy:

Ensure perfect fit and reduce material waste.

✅ Foot-Pedal Operation:

Hold, cut, and release—effortless control for high-repeatability tasks.

Speed up your end-of-line packaging with automation.

✅ Wrap Products of Any Length:

No limit on product dimensions—ideal for custom orders.

✅ Improve Presentation:

Smooth, tight wrapping enhances product appeal and protection.

✅ One-Button Operation:

Automate sensing and wrapping—free up staff for higher-value work.

Eliminate slow, manual fastening processes.

✅ Fasten 3–4x Faster:

Automatic feeding and driving—no more picking screws or pins.

✅ Reduce Operator Fatigue:

Lightweight, ergonomic design for comfortable all-day use.

✅ Built for Heavy Duty:

Taiwan-made core components ensure long-term reliability.